Cabin SOLUTION

“Development Capabilities”

In June 2019, ANH Structure began research and development to localize economy-class lightweight composite seats for large commercial aircraft. Through this project, we are developing lightweight design technology and manufacturing processes for lightweight components while securing consistent development capabilities in reliability verification.

Aircraft Seat Parts Manufacturing

-

Back Cover

Back CoverMeterial : Boltaron

Manufacturing : Press Forming -

Backrest

BackrestMeterial : Carbon Fabric / PPS / Epoxy

Manufacturing : Press Forming -

Seat pan

Seat panMeterial : Carbon Fabric / PPS / Epoxy

Manufacturing : Press Forming -

Seat Pan Tube

Seat Pan TubeMeterial : Carbon Fabric / Epoxy

Manufacturing : Wrapping system / Dry oven -

Baggage Bar

Baggage BarMeterial : Carbon Fabric / Epoxy

Manufacturing : Wrapping system / Dry oven

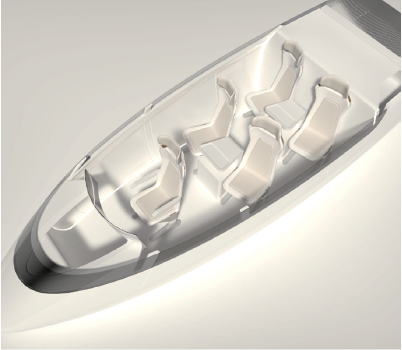

UAM Interior / Seat

· Slim design · Ultra-light design

· 30g Vertical EAS · 4 - point seat belt

Rotary Wing Seat

Bulletproof

Bucket

Non - Flammable

Cushion

Energy Absorption System

For Crashworthiness

Bulletproof

Bucket

Non - Flammable

Cushion

Energy Absorption System

For Crashworthiness