SPACE

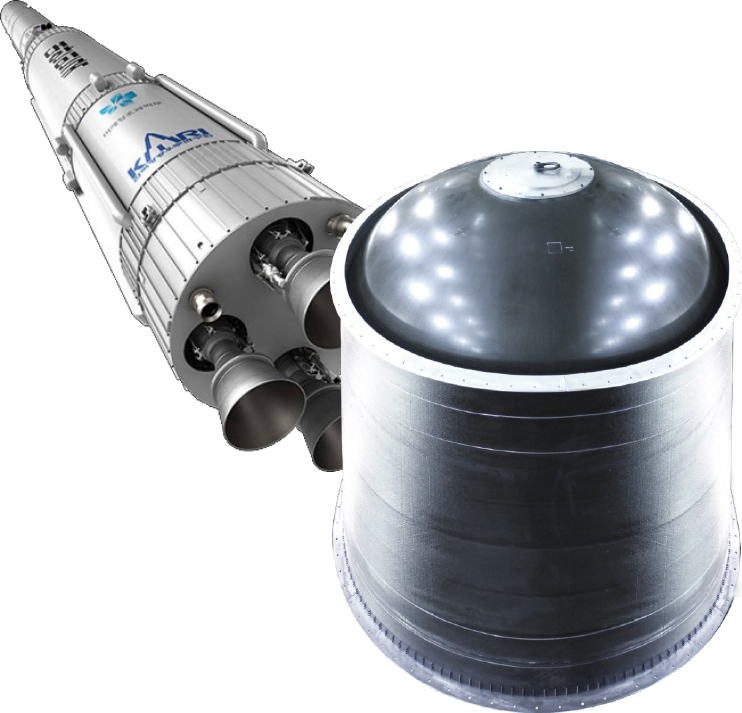

“First in Korea to Manufacture Space Launch Vehicle Composite Tanks”

Using purely domestic technology in composite manufacturing and space sector business, our space launch vehicle composite propellant tanks, developed with our proprietary pure composite manufacturing method, achieved a weight reduction of approximately 23% compared to traditional metal tanks. We have completed cryogenic tests, flight load tests, and permeation tests, thereby owning the critical technology to reduce the weight of existing launch vehicles and secure additional payload capacity.

Scope of Maintenance Capability

· TYPE - V Linerless, Carbon Fiber Composite Propellant Tanks

· Over 30% reduction in weight and manufacturing costs compared to traditional metal propellant tanks

· Secured structural safety against extremely low temperatures and flight loads.

Cryogenic Permeation Test at -196°C (77K)- Proof and Burst Pressure as Additional Conditions

- Over 40 Cycles at MEOP (Max. Enveloped Operating Pressure) in -196°C Conditions

- Minimum 5 Cycles of Thermal Shock (-196°C ↔ 23°C)

- Leak Rate Check @Manhole Cover: Less than 1.07x10^-4 mbar·l/s

- Permeation Rate Check @Composite Surface: Less than 3.10x10^-6 mbar·l/s

Static Flight Load Test- Shearing, Bending, Compression and Fabrication Load as Additional Conditions

Specifications

Specifications

· Oxidizer: LOx

· Capacity: 15,000 L (3,960 gal) & Dimensions

- Diameter: 2.6 m (100 in)

- Height: 3.5 m (140 in)

· Weight: Less than 380 kg (Less than 850 lbs)

- 35-40% Lighter than Traditional Metal Propellant Tanks

Operating Environment

Operating Environment

Operating Temperature Range: -353~144°F (-196~80 °C)